Old Automation of foundry processes

At Iruña we make the most of our capacity and experience in providing solutions to foundries, in order to offer our clients the greatest flexibility and adaptation to their needs and requirements. We develop custom-made process automation projects in casting, in turn-key format.

SOLUTIONS

We offer a wide range of services in automation of foundry processes.

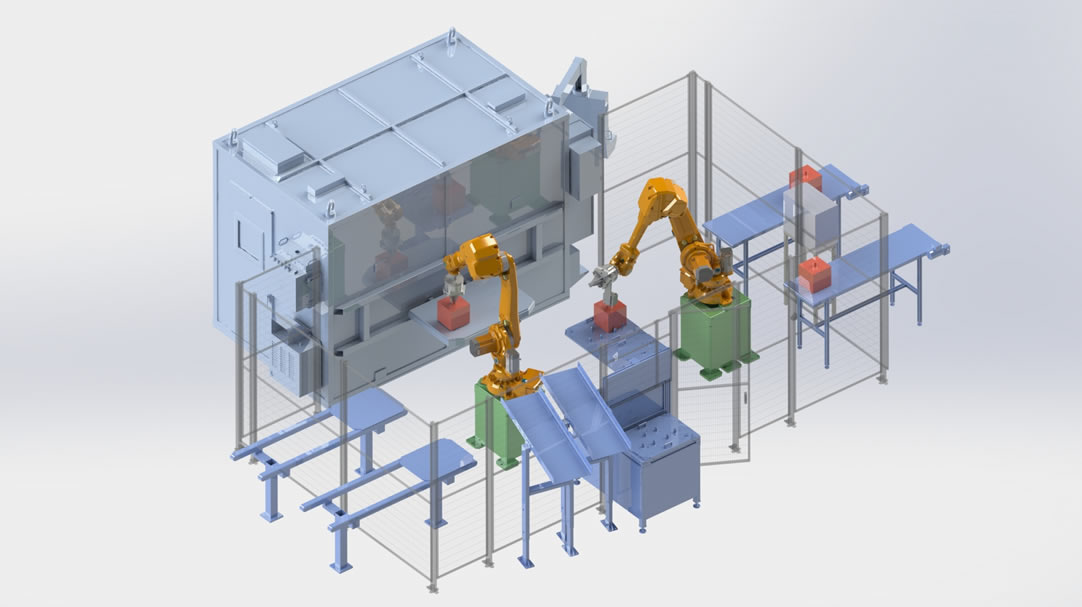

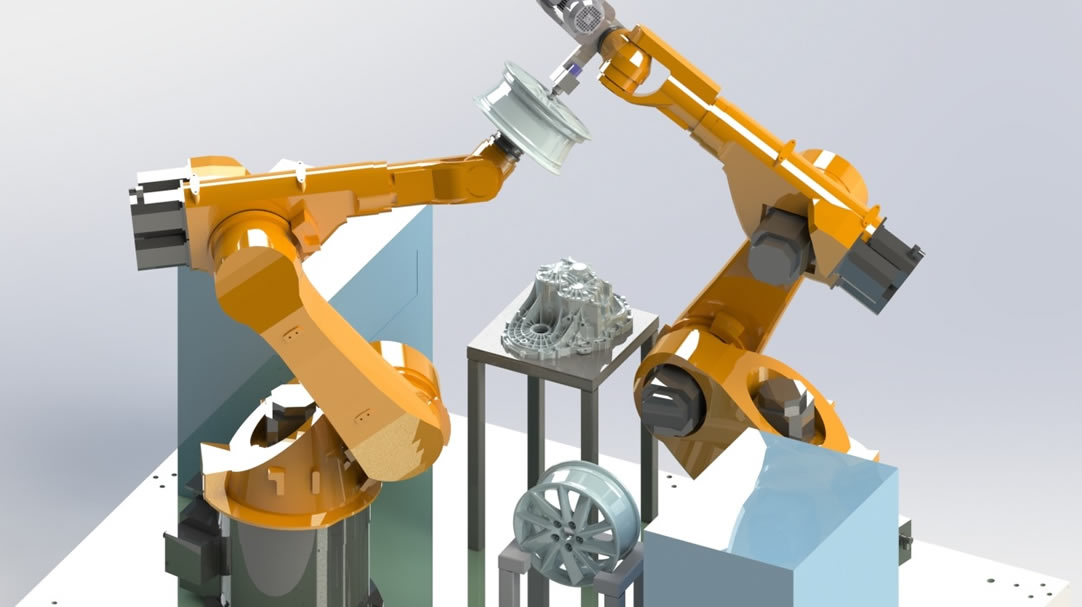

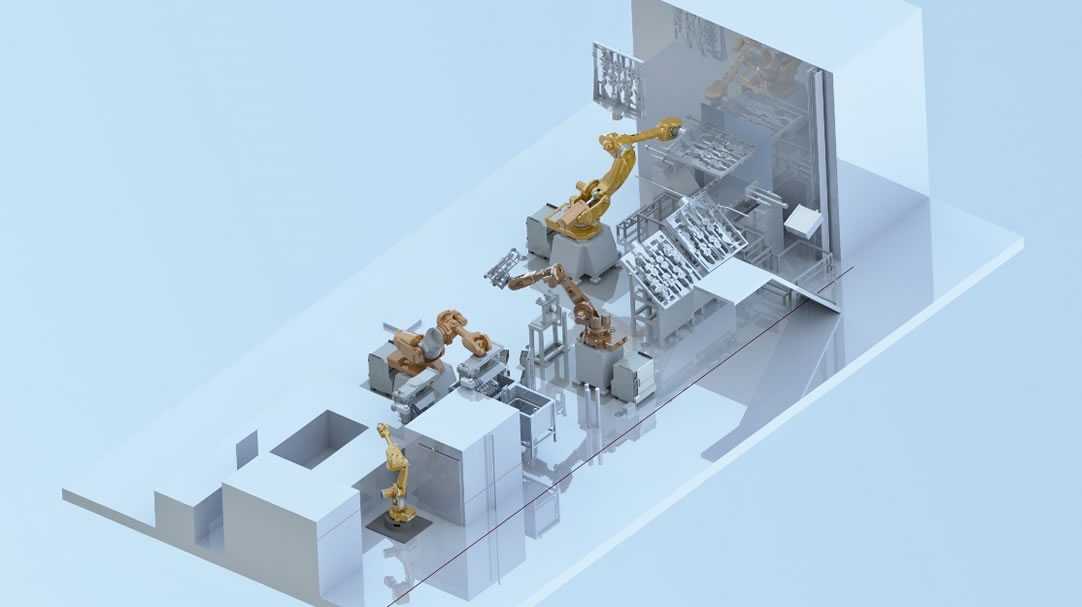

Robotization of manual operations

Robotized marking systems

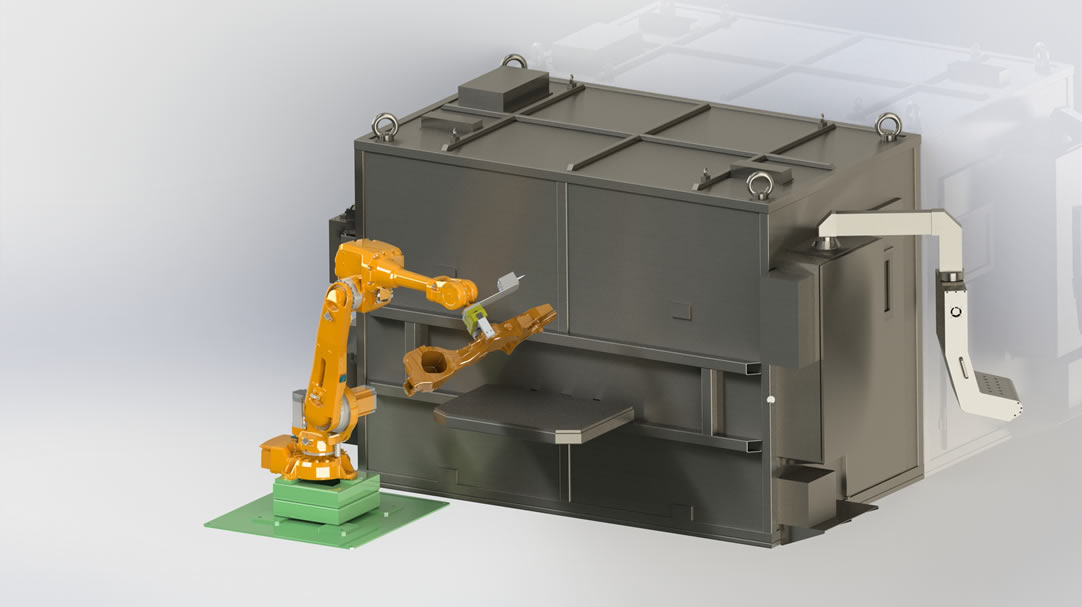

Robotization, deburring, polishing and cutting

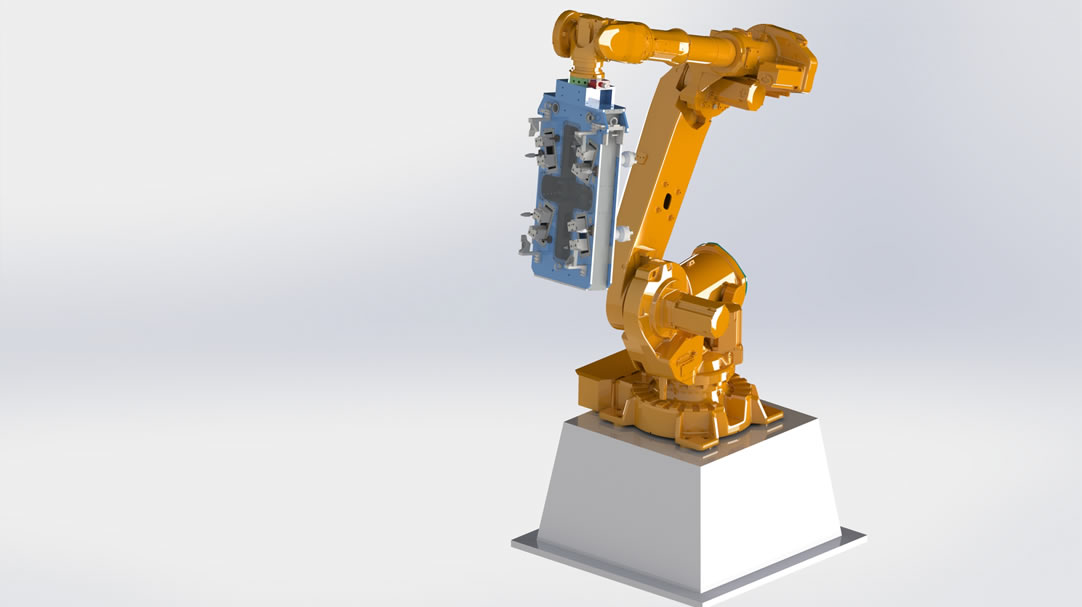

Special Grippers

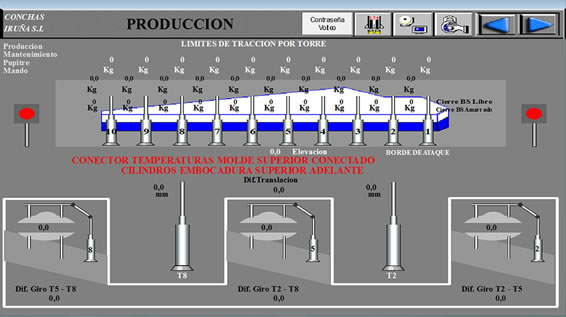

Advanced control systems for foundries

X-ray inspection on production lines

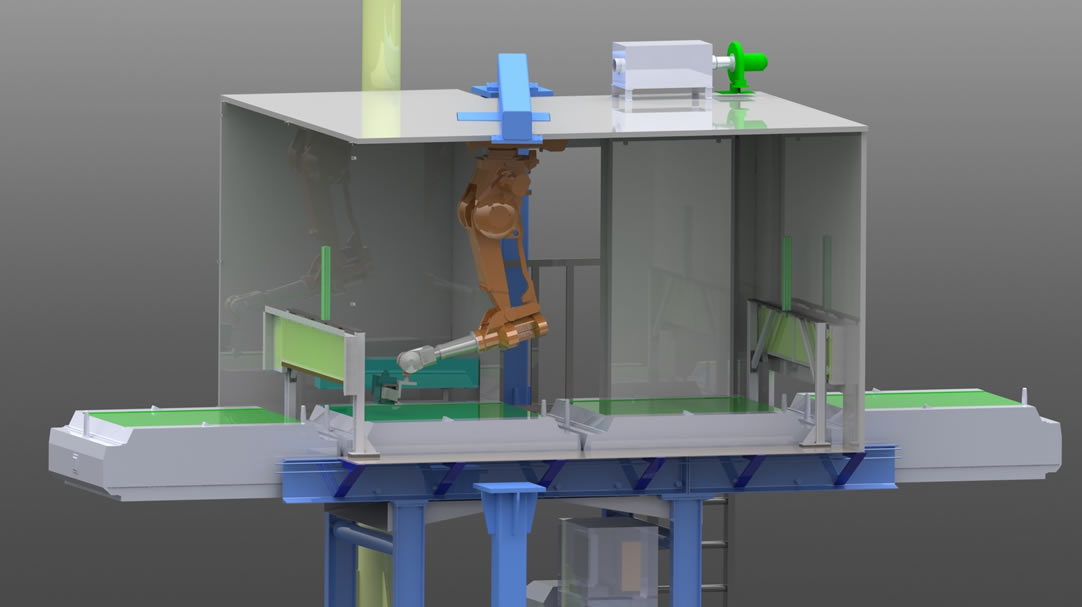

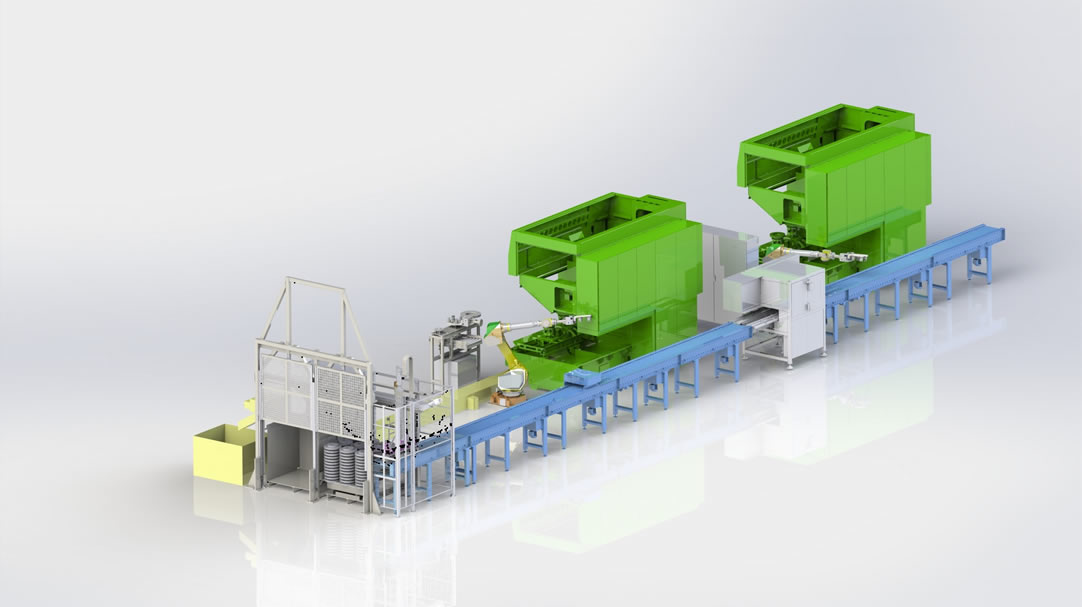

Production lines

Sand core processing lines

METHODOLOGY

At Iruña we make the most of our capacity and experience in providing solutions to foundries, in order to offer our clients the greatest flexibility and adaptation to their needs and requirements. We develop custom-made process automation projects in casting, in turn-key format.

A METHODOLOGY LEAD BY PROFESSIONALS

Iruna’s team has a highly qualified multidisciplinary technical profile. The sales department is composed of engineers able to discern the needs of the customer and offer a technical solution that best suits those needs. The technical office staff is made up of mechanical and electrical engineers, along with programmers who design the best technical solution. For its part, the start-up unit has qualified technicians in charge of the manufacture and installation of each project.

ENGINEERING SERVICES

- 3D and 2D CAD design.

- Calculation of finite elements.

- Production flow simulation.

- Structures and mechanisms.

- Electrical and control systems.

- Robotics and automation

WE PROVIDE

- Equipment and tools involving mechanics, hydraulics, pneumatics and electrical and control systems.

- Robotics and automation of industrial processes.

ADVISORY, TRAINING AND PROJECT MANAGEMENT

We can supervise, train or directly oversee specific projects of our clients.